V/VR polishing filter

Home > Horizontal Plate Filters > V/VR polishing filter

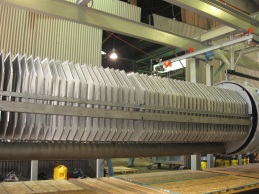

Sparkler® V and VR Horizontal Plate Filters

High Surface Area for Low Solid, Consistent Forward Flow Applications

The Sparkler® V and VR Horizontal Plate Filters are versatile, high-performance filtration solutions that excel in semi-continuous or continuous low-solid polishing applications. These models combine innovative features with a compact design to ensure efficiency, reliability, and ease of operation. While they share many core functionalities, the V and VR filters are tailored to meet distinct industry needs.

- Sparkler® VR: Optimized for use with paper media, offering low cost and easily discardable quick replacement media options with efficient filtration. Common examples include cellulose, polypropylene, Rayon, and more.

- Sparkler® V: Designed for compatibility with wire mesh , or filter bag media, providing robust performance across a wide range of applications and chemical compatibility with reusable media.

Both models deliver superb surface area while maintaining a minimal operational footprint, making them ideal for a variety of manufacturing environments.

Key Features

Filters from both the top and bottom sides of each plate, effectively doubling the filter area within the same physical space compared to standard horizontal plate filters.

Dual-Sided Horizontal Filter Plates

Constructed from materials such as 304 S.S., 316 S.S., Hastelloy, and Carbon Steel, ensuring durability and adaptability to diverse chemical environments.

Customizable Construction

Supports a wide range of filter media, including filter paper, synthetic materials, wire mesh, and membrane media. Click here for more information on Filter Media.

Broad Media Compatibility

Provides robust performance at a competitive price point. The V model's reusable media and the VR model's disposable options ensure lowest operational costs in industrial filtration. 1/10th cost of competitive technologies.

Cost-Effective Operation

Enhances cleanability, ensures zero-heel filtration, eliminates venting requirements, and improves product recovery. Ideal for industries requiring stringent sanitary conditions or high-value products.

Optional Reverse Flow Design

Photo Gallery

Simple Parts List Drawings

Filter:

1. Filter Cover

2. Filter Tank

3. Filter mounting (Portable optional)

Filter Cartridge:

4. Plate Spacer

5. Filter plates

6. Top compression/Lift plate

7. Media

8. Scavenger Plate with Center Column (Optional)

9. Outer Ring

Compression Hardware:

10. Swing bolt closure

11. Side tie rods

12. Center Tie Rod

13. Compression Cap

14. Tie Rod Socket

Miscellaneous:

15. Cover Gasket

16. Tie Rod Socket Gasket

17. Outlet Gasket

18. Air vent

19. Pressure gauge

Ports:

20. Inlet

21. Outlet

22. Drain

23. Scavenger outlet

The Sparkler® V and VR Horizontal Plate Filters have established themselves as trusted solutions in industries worldwide, excelling in polishing applications where efficiency and reliability are critical.

- Food and Beverage : Used in flavoring, edible oils, plant-based foods, fats, vitamins, and more.

- Chemical : Ideal for specialty chemicals, petrochemical additives, resins, and polyols.

- Ultrafine Filtration : Achieves separation down to 0.01 microns using filtration aids like diatomaceous earth (DE) or perlite . Offers significantly lower operating costs than bag or cartridge filters.

- High-Volume Operations : The dual-sided filtration plates enable high flow rates with minimal footprint requirements.

Curious if we’ve handled your specific application? With decades of expertise, the answer is almost always “yes.” Contact us today to discuss how the Sparkler® V and VR Filters can meet your needs.

- Filter Media Compatibility : Supports various filter media options, ensuring adaptability to process needs.

- Sizes and Capacities : Standard diameters include 12″, 1 7″, and 32″, filter areas ranging from 4.7 ft² (0.07 ft³) to 351 ft² (8.24 ft³).

- Specification Options : Click here for a complete description of specifications and options.

Click here for detailed guidance and expert tips on planning single-filter projects — including auxiliary equipment, system configuration, and cost-saving insights. For multi-filter or continuous operation setups, click here to explore additional solutions.

Unmatched Efficiency:

Zero heel, complete recovery of product for maximum efficiency.

Tailored Solutions:

Custom-built designs to meet the unique challenges of your application.

Exceptional Support:

A dedicated team of experts ready to assist with your filtration needs.

With nearly a century of expertise in liquid filtration, Sparkler® Filters provides tailored solutions to meet unique process challenges. Our commitment to innovation, quality, and customer satisfaction ensures that you receive a filtration system optimized for performance and reliability.

Contact Us

For assistance in selecting the appropriate filter type or to discuss customization options for your application, please fill out our Application Data Sheet or Contact us directly at (936) 756-4471. Our team of experts is ready to provide the support and solutions you need.