- Home

- Products and Services

Products

- About

- Resources

- Contact Us

Home > Specifications & Options

When requesting a quote from Sparkler Filters, providing clear equipment details helps us craft the right solution faster. Below, you’ll find a breakdown of our standard offerings, common configurations, and customizable features across our major product lines.

As a custom equipment manufacturer with a wide range of capabilities, not all options are listed here. Contact us for questions, additional requirements or non-standard requests.

| Feature | All Sparkler Filters |

|---|---|

| Construction Code | ASME Section VIII, Division I, U-Stamp and Nameplate |

| Approval Drawing | Provided by Sparkler. Required prior to production |

| Documentation | Three to Four hard-copy detailed operating manuals, code papers, order write-up, dimensional and parts list drawings |

| Warranty | 1 Year |

| Technical Support | Included for the life of the filter. |

Below are common options for related configurations (may not apply to all filter models) :

| Specification | Standard | Optional Upgrades |

|---|---|---|

| Design Pressure | 60 PSIG (>5 PSIG on MCRO units) | Up to 400 PSIG available |

| Jacket Design | Not standard; 14.5 PSIG if included | Up to 150+ PSIG available |

| Design Temperature | -20°F- 350°F | Exceeds 400°F upon request |

| Differential Pressure | 50 psid. | Up to 100+ PSID available |

| Full Vacuum | Not standard. | ASME-rated full vacuum available |

Material is typically selected based on chemical compatibility, expected service life, and cost considerations. For reference, the material options below are generally listed from least to most expensive within each category.

In most configurations, materials of construction (MOC) are divided into three key categories:

These are the components that come into direct contact with the liquid being filtered. Examples include the inside of the filter tank, filter cartridge, plates, and port components.

These components do not contact the process fluid. Examples include the filter tank exterior, support legs or mounting, jacket, swing bolts, lifting devices, and external hardware.

Gaskets provide critical sealing between filter components. Selection is based on chemical compatibility, temperature, pressure, and regulatory requirements.

Surface finish is an important consideration in applications involving sanitary requirements, cleanability, visual inspection, regulatory compliance, or internal quality control standards.

Sparkler will help select the best discharge mode based on your product, solids, and process goals.

| Finish / Treatment | Description |

|---|---|

| Electropolish | Corrosion-resistant, ultra-smooth finish ideal for sanitary and FDA-grade applications. Available standalone or post-polishing |

| Glass Bead Blast | Smooth matte finish that improves visual uniformity and cleanability |

| Hand Polish (60-180 Grit) | Available in 60, 120, 150, or 180 grit to meet specific Ra values |

| Pickling | Removes scale, oxides, and welding discoloration from stainless steel surfaces |

| Passivation | Chemically removes free iron and enhances corrosion resistance; often combined with pickling for full treatment |

| Custom Ra Finishes | Ra-specific polishing available upon request |

| Documentation | Ra verification, Certificate of Finish, ASTM certificates available as options. Click here for more information on certifications and standards. |

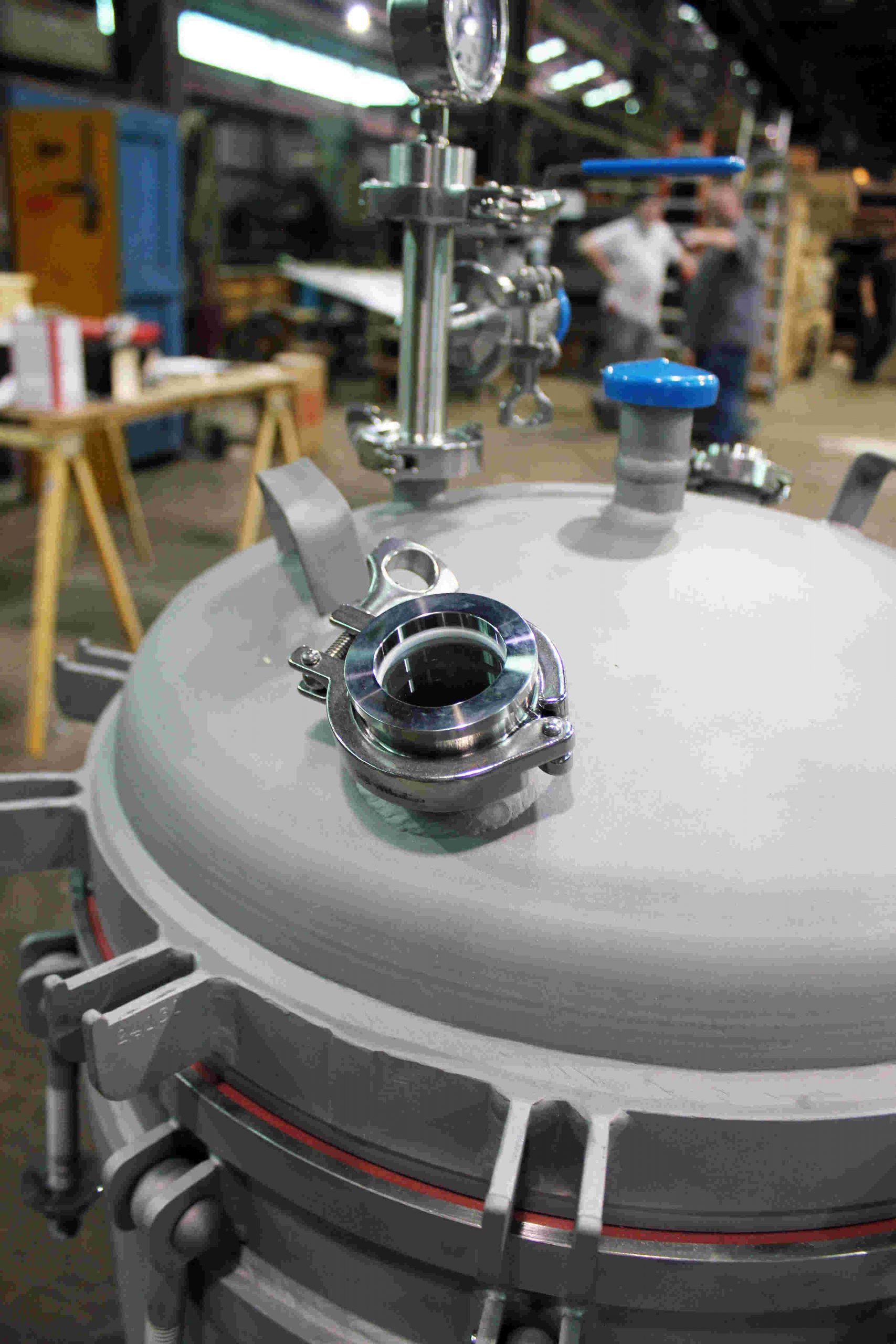

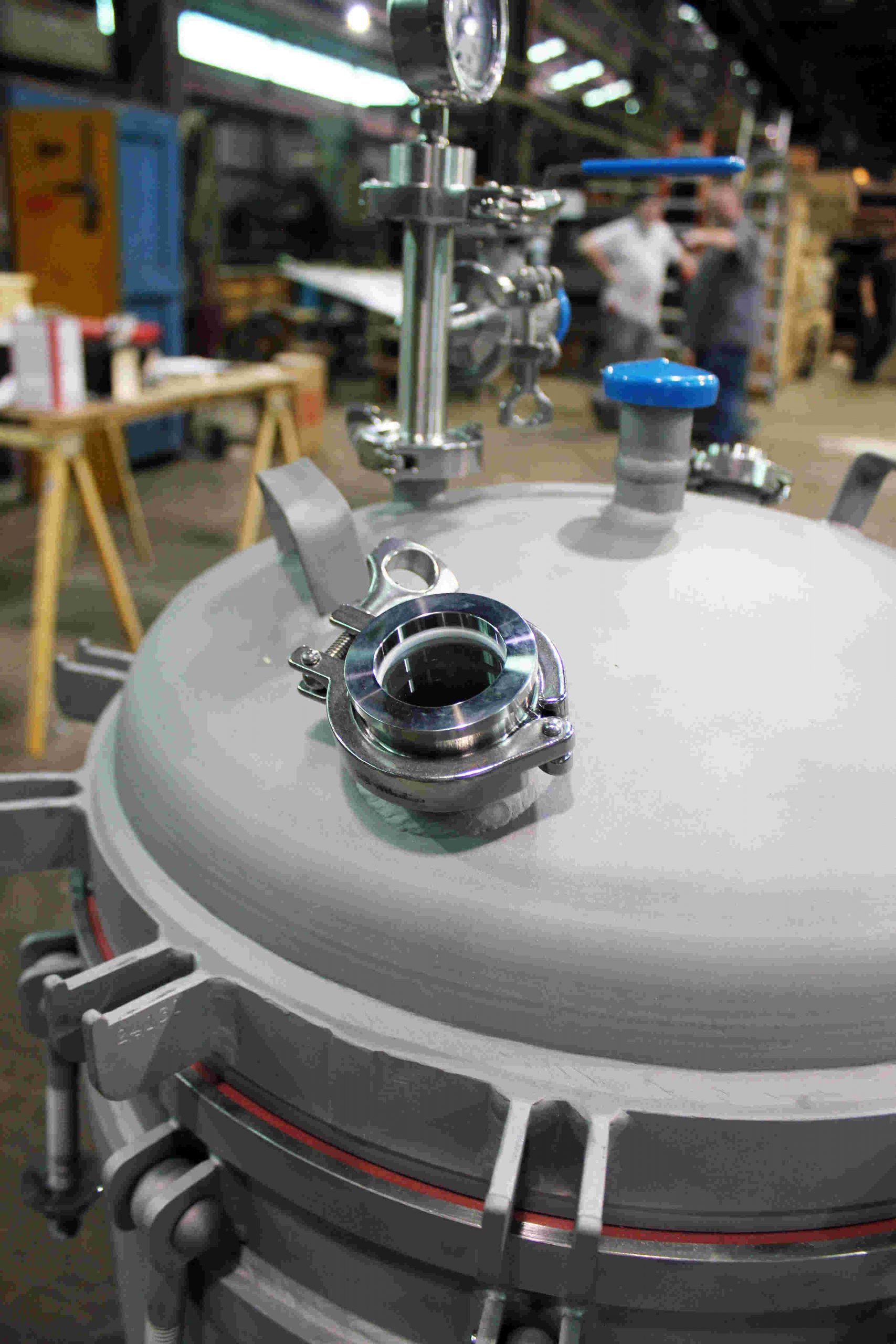

Sparkler® Filters offers fully customizable port configurations to meet the requirements of your process and plant standards. Port type and size affect not only installation, but also cleanability, flow performance, and regulatory compliance.

Sparkler® Filters can be configured with a wide range of mechanical and structural options to meet your operational, mobility, and installation needs. The following options apply to most filter lines, contact us for confirmation.

A scavenger plate is used to minimize unfiltered product remaining in the vessel, especially important in high-value or solvent-sensitive processes where maximum recovery of filtrate is essential. See Step 7 on attached process overview.

Optional jacketed filter vessels are available for temperature-sensitive applications requiring heating or cooling of the product during filtration.

Mounting configurations to suit your space, mobility, and handling requirements :

Simplify installation and improve operator access with optional Sparkler-supplied outlet piping :

Filter media plays a vital role in clarity, chemical resistance, and filtration performance. Sparkler provides a standard recommendation per filter type and size, but customers may always specify alternatives. Learn more about filter media

Whether you're exploring options for a new application or refining specs for an existing one, our team can walk you through the process, step by step. With nearly a century of experience across thousands of applications, there's a good chance we've solved your challenge before.

Contact us today to discuss your application, get expert guidance, or request a quote.

"*" indicates required fields