Custom Solutions

Home > Custom Solutions

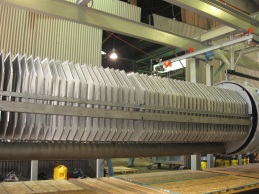

Custom Solutions for Filtration Equipment

Tailored Filtration Solutions for Unique Applications

Have a unique project or need expert advice on integrating new systems into aging plants or mixed equipment setups? Need custom engineering or site-specific designs? At Sparkler Filters, Inc., we specialize in designing and manufacturing custom-built filtration equipment to meet the unique demands of a wide range of industries. With nearly a century of expertise in solid/liquid separation, our ASME-certified U.S. manufacturing facility is fully equipped with in-house American engineering to develop filtration solutions that exceed stringent industry requirements and fully customizable options.

Engineering Excellence & Customization

We collaborate closely with engineering firms and end-users to develop custom filtration solutions that meet exacting specifications. Whether addressing complex chemical processes, pharmaceutical-grade specifications and tolerances, or high-demand mining operations, our team ensures precision, reliability, and efficiency in every custom-built filter.

Key Customization Capabilities

We can modify port type and location, adjust design specifications, alter mounting styles, and integrate advanced automation.

Custom Design Modifications

From 304 & 316 stainless steel, Hastelloy, and exotic alloys, we tailor material choices based on application needs and process compatibility.

Material Selection

We adapt filter area, cake capacity, flow rate, pressure ratings, and media type to match process specifications.

Size & Capacity Adjustments

Our engineers work with clients to ensure seamless integration into current operations, enhancing efficiency and process reliability.

Integration with Existing Systems

Include cake capacity, filter area, flow rate, filter media, design pressure, differential pressure, and more. Click here for a complete description of specifications and options

Specification Options

Our Approach to Custom Engineering

Consultation & Design Review – Understanding your specific process requirements and operational challenges.

Engineering & Fabrication – Developing a tailored solution using high-quality design and reliable manufacturing processes.

Testing & Validation – Ensuring compliance with ASME and industry standards before delivery.

Ongoing Support & Optimization – Providing lifetime technical support, troubleshooting assistance, and performance enhancements.

Special Considerations

While we have the capability to manufacture virtually any filtration equipment, we primarily focus on solid/liquid separation solutions. In rare and extreme circumstances, we may explore additional filtration challenges beyond this scope.

Priority is given to Sparkler Filters customers, quotes, and orders; however, we are often able to assist non-OEM customers by supplying parts for equipment from providers no longer in business — such as replacement filter plates or other essential components. Contact us with photos and dimensions to see if we can provide a quote. Click here for more information regarding non-OEM parts.

Partner with Sparkler Filters

When you choose Sparkler Filters, you gain a trusted American-made solution that prioritizes durability, reliability, efficiency, and long-term partnership. Every filter we manufacture is custom-built to customer specifications, ensuring a perfect fit for your unique process requirements.