Soda Ash Processing

Home > Case Studies Resources > Soda Ash Processing

Soda Ash Processing

Solving Scale-Up and Filtration Bottlenecks

Client : Redacted for confidentiality

Industry : Chemical

Date : 2022 - 2023

Introduction :

A leading chemical company with 25,000 employees, sought to improve filtration efficiency and increase throughput in their soda ash manufacturing. This case study explores customers collaboration with Sparkler Filters to achieve exceptional results.

The Challenge :

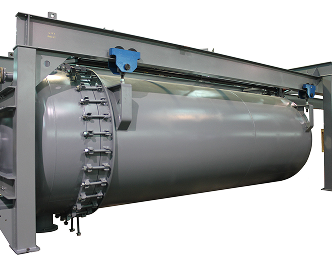

Customers Wyoming facility, equipped with 20 MCRO style filters, aimed to boost throughput by an additional 10%. Achieving this while utilizing existing equipment presented a notable challenge.

The Solution :

Sparkler Filters assessed customers’ needs and recommended targeted solutions:

Precoat/Bodyfeed Efficiency : Sparkler Filters introduced multiple strategies to enhance precoat and bodyfeed efficiency. These included optimizing diatomaceous earth (DE) mixing by combining fine and coarse grades, reducing mixing volume by half, fine-tuning grade of filter media from 200cfm to 80 cfm, reduce recirculation time, increasing precoat flow rate to 1gpm/ft2, along with customized recommendations tailored to each specific filter.

Cleaning Time and Efficiency : To streamline cleaning processes, Sparkler Filters examined sluicing times and cleaning efficiencies. Recommendations included reducing sluice passes to two by adjusting hydraulic speed to 4ft/minute, replacing worn hydraulic needle valves, and optimizing sluice nozzle angles to 87.5, 90, and 92.5 degrees.

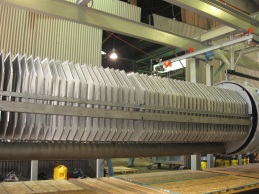

Filter Leaf Spacing : Through close collaboration with customers engineering team, an optimal f ilter area and cake capacity were determined. This involved removing half of filter plates from existing filters to achieve the desired configuration.

Results and Conclusion :

The tailored solution increased throughput resulting in an additional 1,555,516 tons of product annually valued at $10,886,126. Optimized precoat procedure resulted in $631,314 annually in DE savings alone. Precoat time was significantly reduced, even distribution and alternate grades of DE increased filter effectiveness, body feed modifications allowed for higher flow rates, filter leaf spacing adjustments enabled longer cycle times, and cleaning time was slashed from 45 minutes to just 30 minutes.

All new filters at this location are now manufactured to this customized specification, making them the only filters with this unique spacing and plate configuration. By choosing Sparkler Filters as their filtration partner, they achieved substantial cost savings and solidified their position as an industry leader in the chemical sector. This case study highlights the remarkable success achieved in partnership with Sparkler Filters, demonstrating the significant impact that meticulous filtration optimization can have on operational efficiency and underscoring the potential for similar improvements across the chemical industry.