Lithium-Ion Batteries

Home > Case Studies Resources > Lithium-Ion Batteries

Lithium-Ion Batteries

Boosting Efficiency in a Fast-Growing Market

Client : Redacted

Industry : Li-Ion Batteries

Date : 2022

Introduction :

A leading supplier in the anode and cathode industry for Li-Ion Batteries, faced a unique challenge when seeking a filtration solution for their pilot plant. This case study delves into the successful collaboration with Sparkler Filters in designing, manufacturing, and implementing a customized filtration solution that delivered exceptional results.

The Challenge :

Customer needed a filtration system capable of withstanding a highly corrosive environment while accommodating a high-flow rate application with approximately 1% solid content. The use of Diatomaceous Earth (DE) was not viable for their process, necessitating an alternative cellulose-based solution. Budget constraints also required a manual system capable of running uninterrupted for several days without operator intervention.

The Solution :

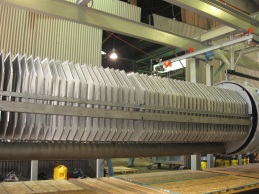

Sparkler Filters embarked on a comprehensive review of the project with our engineering team. The result was the creation of an unparalleled horizontal plate filter, boasting an expansive 383 ft² surface area and a substantial 36 ft³ cake capacity. This filtration behemoth comprised 39 polypropylene filter plates housed in a ~8ft rubber-lined tank, with C-276 compression components providing required stability and durability.

Results and Conclusion :

The installation of the custom filtration system proved to be a resounding success. Given the challenging high-flow and corrosive environment, Sparkler Filters continued to work closely with customer for several weeks post-commissioning. The goal was to fine-tune the filtration process and establish a standard operating procedure that consistently met expectations.

At Sparkler Filters, we stand as your committed partner throughout the filtration journey, from the initial design considerations to the point where your desired results are achieved. This case study serves as a testament to our dedication to meeting and exceeding our customers' process goals.