Dry Cake Discharge (DCD)

Home > Dry Cake Discharge (DCD)

Dry Cake Discharge

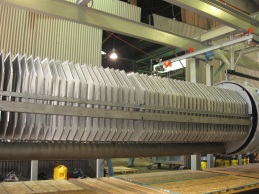

Self-Cleaning with Vibrating Vertical Plates

Dry Cake Discharge (DCD)

Easy, dry solid recovery or disposal.

Dry Cake Discharge (DCD) is Sparkler's operator and disposal friendly method of solids removal from vertical plate filters—using just air operated vibration. Designed for applications where a slurry is not feasible or preferred, the DCD system uses mechanical vibration to knock dry cake off vertical filter plates once filtration is complete.

How It Works ?

Once filtration is complete, a hydraulically operated quick opening cover is unlocked and the tank shell or bottom is retracted hydraulically, exposing the filter plates. A pneumatic vibrator is then activated, causing the plates to release the dry cake in the form of solid sheets or chunks. These solids fall by gravity into collection bins or onto conveyors for disposal, collection or further processing.

Key operational components :

- Filter tank is opened with each completed cycle

- Hydraulic systems manage opening/closing cover and tank retraction/detraction

- Pneumatic vibrator removes cake from plates—no liquid required

- Filter is closed and reset for the next run in minutes

- Proximity switches confirm filter lock, ASME vent, and retraction positions

- Cake typically contains <10–15% moisture by weight, depending on process

- Precoat recommended for most fine filtration processes

No wash, No Slurry. Just clean plates—and dry cake that’s ready to handle.

When to Use Dry Cake Discharge

DCD is ideal for :

- Solids that need to be low moisture for disposal, recovery, or reuse

- Processes that require no additional liquids in the discharge

- Applications where liquid sluicing is not available or preferred

MCRO models using DCD are commonly found in mining , chemical , petrochemical, metals recovery, and high-solid specialty chemical applications.

VF models using DCD are found in a wide range of industrial applications but are highly favored in food and beverage , biofuels, petrochemical and chemical industries.

Design & Performance

Available On :

MCRO Vertical Plate Filter (40–2,000 ft² range)

VF Vertical Plate Filter (38–660 ft² range)

Automation

PLC Controller : Spec’d to your requirements. Local operator control.

DCS : Proximity switches and solenoids can be integrated into plant DCS.

Both : Dual-mode control allows for maintenance override or backup control.

Control Logic Provided : Sparkler supplies base logic and can assist with custom sequencing.

Standard Flow Rates for Sluicing

3 bursts of air ~10 seconds each, with 5 seconds off between bursts

Can be configured to continuous or timed cycles depending on application

Materials of Construction

Click here for a complete view of specs and options.

- 304/316 Stainless Steel, Hastelloy, Carbon Steel, Rubber-lined, Duplex

- Filter plates in wire mesh or high-release synthetic monofilament

- ASME-certified pressure vessels

- Polypropylene, wire mesh, and monofilaments for optimal cake release

- DE or Perlite precoats recommended for micron capture <40µ

Why It Works So Well

✔️ No Liquid Required : Perfect for operations where water/product is limited or unwanted in final solids

✔️ Operator Accessible : Filter shell retracts and exposes plates directly with access to each plate—making inspection, cleaning, or media replacement easy

✔️ Efficient Cake Drop : Engineered plate and media combinations release cake with minimal vibration

✔️ Quick Turnaround : Full cleaning cycle can be completed in minutes—no need for drainage handling

✔️ Durable System Design : Proven in high-throughput, high-solids operations with minimal maintenance requirements.

Disposal Options

DCD cake is discharged dry and ready for further handling. Common methods include :

Conveyors for continuous transport

Screw press for further drying and processing

Bin or Hopper collection for disposal or reuse

Sparkler can help design your downstream handling system to match discharge characteristics.

DCD vs. WCD — Which to Choose?

| Feature | Wet Cake Discharge (WCD) | Dry Cake Discharge (DCD) |

|---|---|---|

| Cleaning Method | Liquid sluice jets | Vibrating filter plates |

| Cake Format | Slurry or semi-slurry | Low moisture, solid sheet or chunks |

| Vapor Exposure | None or Minimal | Open Tank to Discharge |

| Solids Removal System | Pump-out | Vibration or Manual |

| Filter Aid | Optional ~5 – 100 micron | Required under ~40 micron |

Need both options? Sparkler can configure MCRO filters with both WCD and DCD capabilities in a single unit.

Need help deciding which fits your application? Contact Us for an application consultation.

Ready to optimize dry solids recovery?

Let Sparkler’s engineers help you integrate Dry Cake Discharge into your operation. Whether you’re planning a new project or want to reduce disposal cost and moisture content, we’ll design the right system for your goals.

With nearly a century of liquid/solid separation experience, Sparkler Filters continues to innovate in filtration performance. Our DCD systems are built to deliver years of rugged, consistent operation in the most demanding environments.

Built to ASME Code

Lifetime Technical Support

Custom Engineered for Your Solids

Performance-Driven Design