Bridging Solids

Home > Bridging Solids

Bridging Solids in Filtration :

What It Is, Why It Happens, and How to Avoid It

In the world of solid-liquid separation, bridging solids represent one of the most dangerous and misunderstood problems in industrial filtration systems. When left undiagnosed or untreated, bridging can lead to catastrophic failures, inconsistent filtration performance, or costly repairs or downtime. At Sparkler Filters, we’ve worked with countless operators and engineers to troubleshoot and prevent this phenomenon—and we’ve seen firsthand how small changes in process or equipment can yield massive improvements in reliability.

What does “Bridging Solids” mean?

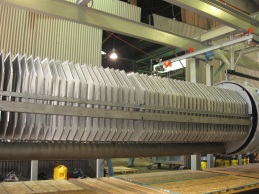

Bridging is when solids filtered exceed the recommended limits of loading capacity. These solids may momentarily “hold together” and create a bridge-like formation, giving the illusion of continued flow. In reality, liquid may still pass through—but solids completely fill the filter plate section of the filter and form a “tube” that converts the filter area from a structured, organized multi-plate system to a cylindrical form often with extreme pressures. Bridging fractionalizes functional filter area and multiplies cake depth; increasing differential pressure and reducing flow rates.

What Causes Bridging ?

Bridging is typically caused by :

- Extended Run Time : Operating the filter too long without discharging can lead to cake buildup that bridges across the cartridge. Filters should be cleaned or discharged before solids reach this point.

- Incorrect Process Variables : Miscalculations in solids loading percentage, specific gravity, or flow rate can result in improper solids distribution.

- Excessive Precoat Application : Precoat should be applied evenly and lightly—approximately 1/8” thick on each plate. Overcoating reduces available space for cake buildup and can contribute to early bridging.

- Overuse of Bodyfeed : Bodyfeed should be dosed at the minimum effective rate required to maintain flow and porosity. Excessive bodyfeed can clog pathways and increase the risk of solids arching or plugging.

- Mechanical Issues : Bridging can also result from improper installation or the use of non-OEM parts , gaskets, or filter bags. These components can alter clearances, disrupt flow, result in improper cleaning and lead to premature loading and failures.

Why It’s Dangerous

Bridging solids create hidden but severe risks that can lead to equipment damage, process failures, and safety hazards. Once solids stop entering the filter plates :

- A high-pressure “tube” forms inside the cartridge, converting the filter from a distributed multi-plate system into a dense, cylindrical mass. This drastically reduces effective filtration area and increases differential pressure.

- Extreme mechanical stress occurs internally, where stainless steel components can be forced apart, crushed, or even torn.

- dP readings may remain steady, and flow may continue—giving operators a false sense of normal operation. The issue often goes unnoticed until mechanical failure or product quality issues arise.

- Overpressure risks escalate, endangering both the equipment and operator safety.

- Cycle times become erratic, with inconsistent throughput and unpredictable solids capture. Downstream processes dryers or reactors may suffer from reduced filtration area.

Engineering Insights & Prevention

At Sparkler, we take a proactive approach to bridging—because prevention is always more effective (and less costly) than repair. The following best practices can help maintain optimal performance and extend filter life:

Design Recommendations

- Properly size the filter for expected throughput, solids loading, and cycle frequency. Check out this article on equipment selection

- Analyze and test your process solids, including solids percentage range and specific gravity, to inform sizing and media selection.

- Determine the ideal trigger for cleaning or discharge, whether by cycle time, dP, or processed volume.

- Always use OEM parts and filter media, and follow Sparkler’s installation and torque guidelines to ensure proper sealing and performance. Check out this page for case examples of OEM vs non-OEM.

Process Adjustments

- Maintain flow rates within the filter’s design range to avoid uneven loading.

- Use recommended precoat and bodyfeed dosages to ensure effective filtration without bridging.

- For consistent solids loading, go to cake discharge at a predetermined fixed interval based on time or total throughput.

- For variable or unpredictable solids, clean when differential pressure (dP) reaches a pre-established threshold.

Monitoring Tips

- Maintain detailed batch log and conduct post-run inspections, including reviewing cake distribution and plate loading. Looking at the evidence to understand root cause if valuable.

- Track the initial rise in dP and monitor for sudden increases (or drops) that may indicate bridging or media bypass.

- Log all available process data (inlet pressure, outlet flow, temperature, dP, cleaning intervals, etc.) for ongoing performance analysis and troubleshooting.

We Can Help

Solving bridging issues requires an understanding of filtration theory, process dynamics, and practical operator experience. Whether it’s a horizontal plate filter, vertical plate filter or any other non-Sparkler filter—our engineering team is here to assist.

Contact us for a diagnostic review of your filtration cycle or explore our Process Consulting Services.